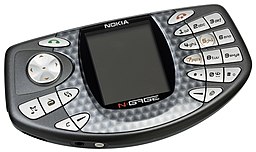

In early 2004, I joined the small Nokia Lifeblog team to lead sales and marketing. Over the roughly 18 months I was with the team, I learned so much about the fusion of internet and mobile, became the first in the company using blogging in marketing and influencer outreach, and engaged with a huge range of characters (many who were foundational to what was then called Web 2.0).

When the team was dissolved in June 2005, I spent the next few months in relative obscurity within Nokia (another interesting story in itself) working on an idea, inspired by all the work I’d done with Lifeblog.

Basically, I saw that the web was fragmenting (into morsels, is what I said back then) as media and social streams multiplied. My vision was a way to bring all those morsels into one view, on any platform, and to remix and republish as folks found, used, and shared social media.

You have no idea how that was so alien to many I spoke with. I learned the hard way the difficulty of articulating something folks could not see.

Nokia Cloud

In 2006, I was picked up by the Multimedia product management team, to focus on the online side of things (I had PC and a Mobile peer product managers). By the end of 2006 I had managed to secure a fuuuuuckload of money (I’ll never be giving that kind of money ever again, I suppose) to work with IDEO (who brought in Digital Foundry (DF) and R/GA for the technical and visual) to make my idea become reality.

We called it Nokia Cloud.

Cloud.

In 2007.

Yup.

In any case, I must say, 2007 was a wicked amazing year, working with really smart and enthusiastic folks. The cool stuff was doing field research (which did a good job of validating what I envisioned) and design workshops to refine the ideas, which R/GA and DF made tangible in designs and early protos. The not so cool was the pressure from a multi-billion euro company wanting the product to be immediately available in a zillion countries and languages, and what I called the Nokia Jello – when a big company just can’t help but kill your agility (no pun intended, we were the first to introduce Agile to a traditionally Waterfall company process).[1] And not sure if it was cool or not when we went to launch the service, by then called Ovi (“door” in Finnish), at Nokia World 2007, that Orange had taken out a full page ad in the FT to warn us off.

iCloud, but before iCloud[2]

The spirit of my vision drove Nokia Cloud. You could see it in the way Ovi was described as the ‘door’ to your online services, which was sort of the way I always described my vision.

With Nokia Cloud, you’d have an app on your phone and desktop that would, through a single view, help you see various levels of your social streams and media (peek), get details (reveal), or dive into the social media service (dive) – providing a range of interaction to rapidly go through and remix all your streams. In the early days, I also wanted to apply some analytics to help folks find and manage everything (Last.fm style, which was a big thing back then).

We were also inspired by the Sidekick Danger (same founder as Android), where all your mobile life was backed up and like a soul, could be placed into another device should you lose one or get a new one.

One cool feature that came up was a ‘stub’, where you start something on one platform, say your mobile, and then grab the stub on another, say your PC, and complete the task. Of course, in the past few years, you can do such things with your iPhone via Handoff. But we wanted to do this back in 2007.

Alas, we spread product dev out in phases and the Danger-like phone contacts and calendar and media recovery were the first to roll out. But I left the team before any of the later parts were rolled out (I don’t know if they were ever rolled out, actually).

I wish I had kept my notes, as so much of what we saw then foresaw where mobile and internet were going. That the iPhone and Facebook were taking over the world in 2007 served as a background for what Nokia had to get right, and fast.

And while we’ve come so far since back then, the world didn’t go the aggregation route I had hoped for (open, choice for all, competition), but instead the world doubled down on stove-piped platforms – Google, Apple, Facebook – where users stayed in walled-gardens, just like the mobile operator walled gardens at the time we had all hoped would be busted open by an open internet.

I did have a bit of a fantasy that Nokia could be the one to stave off the dominance of what became FAGMA (or is it MAGMA, now?). Nokia’s mission was ‘Connecting People’, and the greatest social media network was the contacts in your phone. I wanted to make the phone the door to your online life, and I wanted Nokia to do it.

Alas.

Fifteen frakkin’ years

I left the Cloud team in early 2008, for various reasons, but mostly how I thought I’d not be able to contribute effectively in the new re-org that had just happened (the ones that stayed behind were more than capable to carry on). But what I did during the time I led Nokia Cloud taught me so much about design, products, the fusion of hardware and software, organizational structures, and how to convert disparate insights into a coherent manifestation (and evangelize it).

Since the launch of iPhone in early 2007 was a big thing for us on the brand new Nokia Cloud project, I usually use the anniversary of the launch to take stock of how things have progressed since 2007.

Sadly, when I see where we are today after 15 years, I’m a bit disappointed: NFTs, crypto, Web3, MetaFrakkinVerse – not sure these are anything new, as it all seems way derivative or gimmicky.[4]

Though, in many ways, what I see folks trying to do with their social networks, media, personal narratives, is still the same as in 2007. The difference is that the MAGMAs of the world are dictating the interactions, tastes, and content – so we’re all in the passenger seat, more passive than one would think. Indeed, the medium defines the messages, and so long as MAGMA serve as the pipes, we need to engage with each other on their terms.

Alas, the MAGMAs of the world are just getting more ingrained in our lives and I do wonder how we break that stranglehold. Which is rich coming from me: I am very much beholden to the Apple ecosystem. I am railing from inside the asylum, so to speak.

Next fifteen

I have no idea what the next fifteen years will bring. My interests still reside in the intersection of data, internet, software, and hardware. Not sure where it’ll take me, but I’m a tad wiser. Looking back at the Nokia Cloud project and what it could have been reminds me, again, how I should trust myself more and fight for the visions I see as important.

And sad that this insight might be all that remains from such a fun time.

[1]Make no mistake, I thank Nokia from the bottom of my heart for the freedom and opportunity they gave me. I would not be where I am today without what Nokia provided me in my tenure there, especially during the time working on Nokia Cloud. There were no assholes (well, maybe one or two, but I didn’t have to deal with them for Nokia Cloud), just a bunch of enthusiastic folks who had a track record of doing great things. I am grateful to Nokia for permitting me to work with such folks.

[2]You won’t f-in believe me ever, but in 2002, a few months after we had launched our smartphone[3], I proposed some sort of app[3] that would serve as a market place for folks to read up on apps and download new ones. As I was already oversubscribed, a colleague on my team was given a budget and built it. Funnily, the mobile phone biz dev folks who were appeasing the operators flipped and took over the project and made it their own to let the operators use the on-phone portal for their own apps. Yup. Basically, the app store, long before the App Store. From 2002.

[3]What, you think the iPhone in 2007 was the first smartphone? And did you think the iPhone was the first smartphone to have apps? Oh, gosh, you have a lot of history to catch up on. Haha.

[4]Ok, perhaps I’m not one to judge. I think all of Western Civilization is a footnote on GrecoRoman history – they did it all, in sandals and togas, 2000+ years ago.